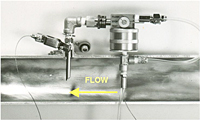

The Mini Monitor Kit Mark II is used to test aviation fuel for particulate contamination using the procedures described in ASTM D2276. A measured volume of fuel is passed from a flowing pipe directly through a 0.8 micrometer membrane. The plastic monitor holding the membrane is placed in an aluminum housing. Dirt particles are caught on the membrane which can be visually color-rated or weighted for a gravimetric rating.

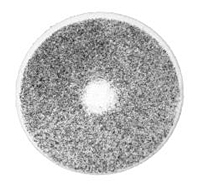

In the new Mark II design, the inlet fuel to the plastic monitor is dispersed laterally to insure a more uniform distribution of particles over the entire surface.

The Mark II version has the unique advantage of eliminating the white spot in the center of the membrane (see photograph below, a membrane not used in the Mark II Kit), which is caused by the fuel entering the monitor at a high pressure. The drawing found on the GTP-172H item page shows how the fuel is dispersed laterally, avoiding the jet effect.

The Mini Monitor Kit is built with stainless steel parts, ensuring that the test sample comes in contact only with stainless steel before reaching the filter membrane. This Kit was developed specifically for aircraft fuel testing with standard field monitors, and weighs only 4 pounds with carrying case.

GTP-172 includes*:

Carrying case, assembled housing and selector valve, bonding and grounding hose assembly, GTP-165 syringe, sampling kit GTP-5, GTP-2099 tweezers, GTP-1074-1 color rating booklet, GTP-1985-6 plastic monitors (6), and GTP-1267 Mini Envelopes (15).

*Photographed on GTP-172 item page.

GTP-172H includes:

Mini Monitor Mark II housing, valve, and complete hose assembly.